Advanced Physiological Optics Laboratory

Yoon Lab

In order to understand how an optical element is affecting performance of an optical system it is necessary to measure optical quality (wavefront aberration) of the element. We developed a high resolution Shack-Hartmann wavefront sensor to measure various optical components including ophthalmic lenses such as contact lenses and intraocular lenses.

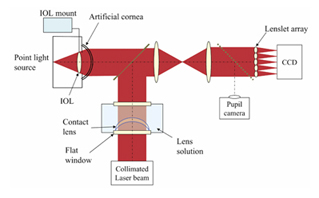

We have designed a high resolution Shack-Hartmann wavefront sensor to characterize the aberrations for both contact lenses and IOLs.

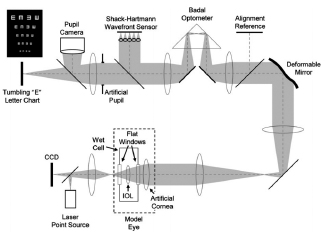

Figure 1: A schematic diagram of the Shack-Hartmann wavefront sensor, illustrating both the contact lens and IOL measurement arms.

A schematic diagram is shown in the above figure for the layout of our high resolution wavefront sensor. The sensor mainly includes wet cells containing either a soft contact lens or an IOL and a high resolution lenslets array. The soft contact lens was immersed in saline solution to prevent lens dehydration and deformation. The IOL was also placed in saline solution to mimic the conditions that the lens would encounter in a living eye.

The Yoon lab has been working to develop customized soft contact lenses (CSCL) containing irregular surface profiles. These lenses may be considered a practical, non-surgical correction method to compensate for the eyes' higher order wavefront aberrations (HOA). Conventional methods for measuring contact lens power, such as lensometry, cannot evaluate the HOA generated by the irregular surface profile. We have been reliably measuring the HOA in these custom contact lenses using the high resolution wavefront sensor. Because of the smaller refractive index difference between the soft contact lens (nlens) and lens solution (nsolution) than between the contact lens and air, the measured wavefront (Wwater) will be less than the lens generated aberrations in air. By multiplying the measured wavefront (Wwater) with a conversion factor (CF), the lens generated aberrations in air can be calculated. The conversion factor (CF) can be calculated according to the following equation.

![]()

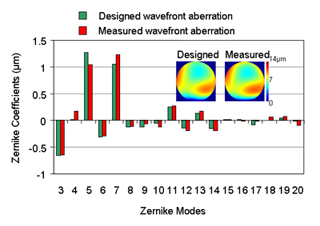

Based on this method, customized soft contact lenses were measured. The figure below illustrates the designed and the measured values for a customized soft contact lens (lens aberrations have been converted to the aberrations in air). The designed and measured aberrations for the lens correlate well.

Figure 2: Designed and measured wavefront aberrations for a customized soft contact lens.

An optical bench test system has been developed for the complete characterization of monofocal and premium IOLs. This method combines adaptive optics with a system to measure the point-spread function and capture images of a resolution target.

Figure 3: A schematic diagram of the adaptive optics IOL optical bench system, which combines a Shack-Hartmann wavefront sensor, with an arm to directly measure through-focus image quality in the presence of corneal aberrations induced with the deformable mirror. (Zheleznyak et al. JCRS, 2012)

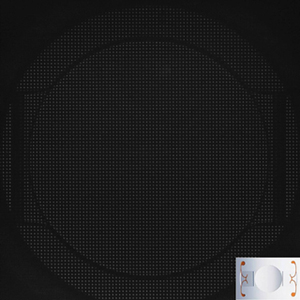

Figure 4 shows an example image of the lenslet for the spot pattern of a premium IOL, the Crystalens HD from Bausch & Lomb. The 5 mm clear aperture of this IOL is sampled with a resolution of 66.7 µm. This results in over 6,000 data points for a 5 mm pupil. Typical commercial wavefront sensors have approximately 5x less resolution.

Figure 4: Lenslet array spot pattern for the high-resolution Shack-Hartmann wavefront sensor as viewed measuring a premium IOL (Crystalens HD, Bausch & Lomb). (Kim et al. JCRS, 2011)

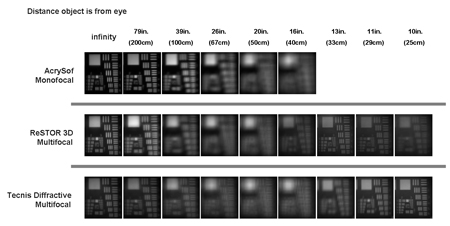

The figure below shows captured images of a resolution target through focus of the multifocal ReSTOR 3D, Tecnis diffractive multifocal lens and a standard monofocal design:

Figure 5: Images of a 1951 USAF resolution target, through a monofocal, ReSTOR 3D multifocal and Tecnis diffractive multifocal IOL in a model eye, through focus: far (left) to near (right).

These lenses provide good image quality, but each lens differs in what it is trying to optimize with its corrections. The monofocal lens has good far image quality and a relatively short depth of focus, whereas the ReSTOR 3D and Tecnis diffractive sacrifice far image quality for extended depth of focus. We also have found the corneal astigmatism has a significant impact on depth of focus. Furthermore, although multifocal IOLs have a significantly larger depth of focus as compared to monofocal IOLs, this advantage is diminished in the presence of more than 0.75D of corneal astigmatism.

It is the goal of the work to further optimize multifocal lens designs using various amounts of higher order spherical aberrations and possible other aberrations in order to maximize the image quality and depth of focus for patients suffering from presbyopia and not wanting to rely on glasses or contacts to improve their vision.

The optical bench test system is a useful tool for the measurement of optical elements. It is the goal of the Yoon lab to perfect not only the wavefront sensor for more accurate and repeatable measurements but also to improve upon current corrective lens technologies to further advance visual quality and care.